INFRASTRUCTURE

At Tamilan Raj Engineering Private Limited (TREPL), we understand that a strong foundation is essential for exceptional results. Here’s a glimpse into our infrastructure that empowers us to deliver high-quality VMC machining solutions:

Why Our Differences Make Us Special?

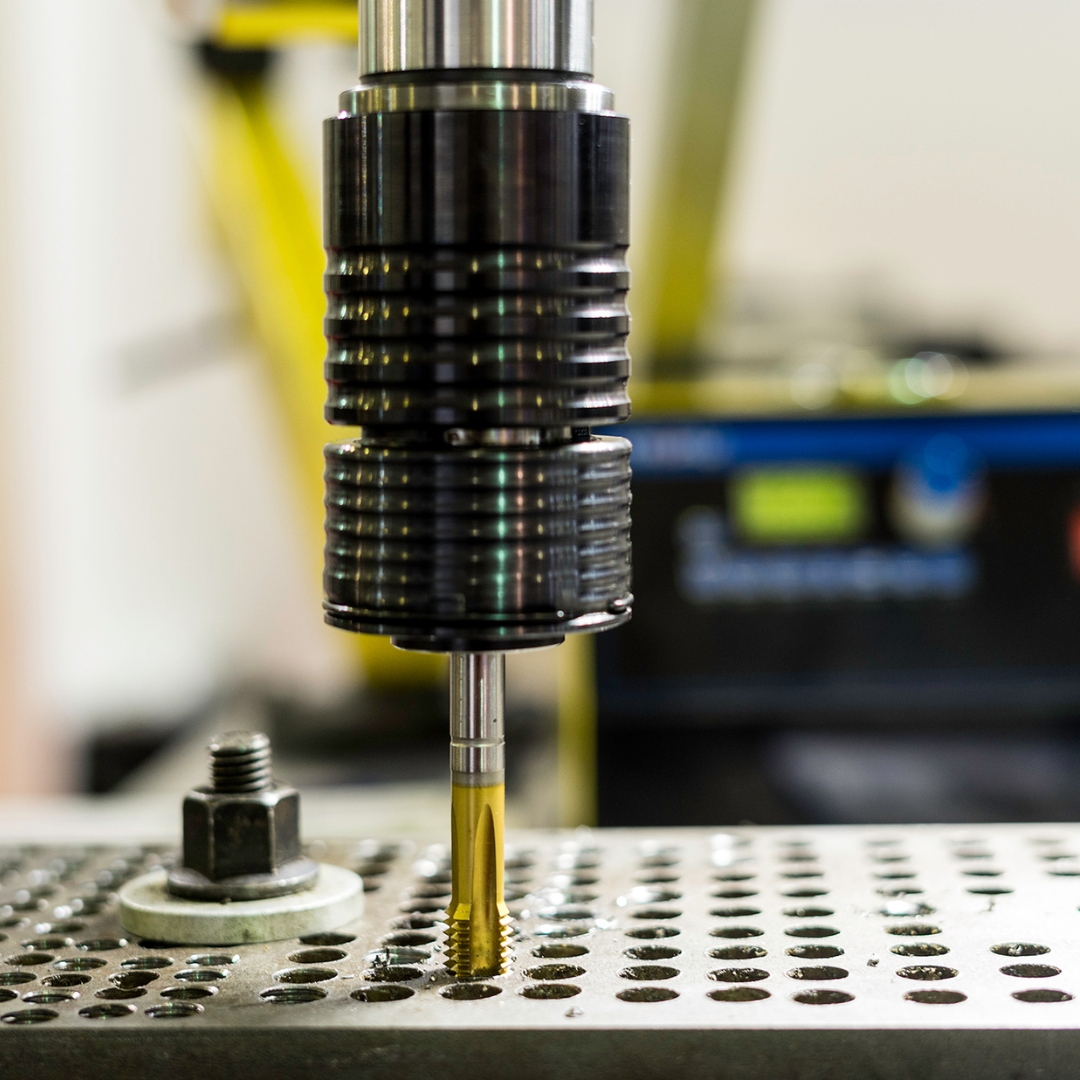

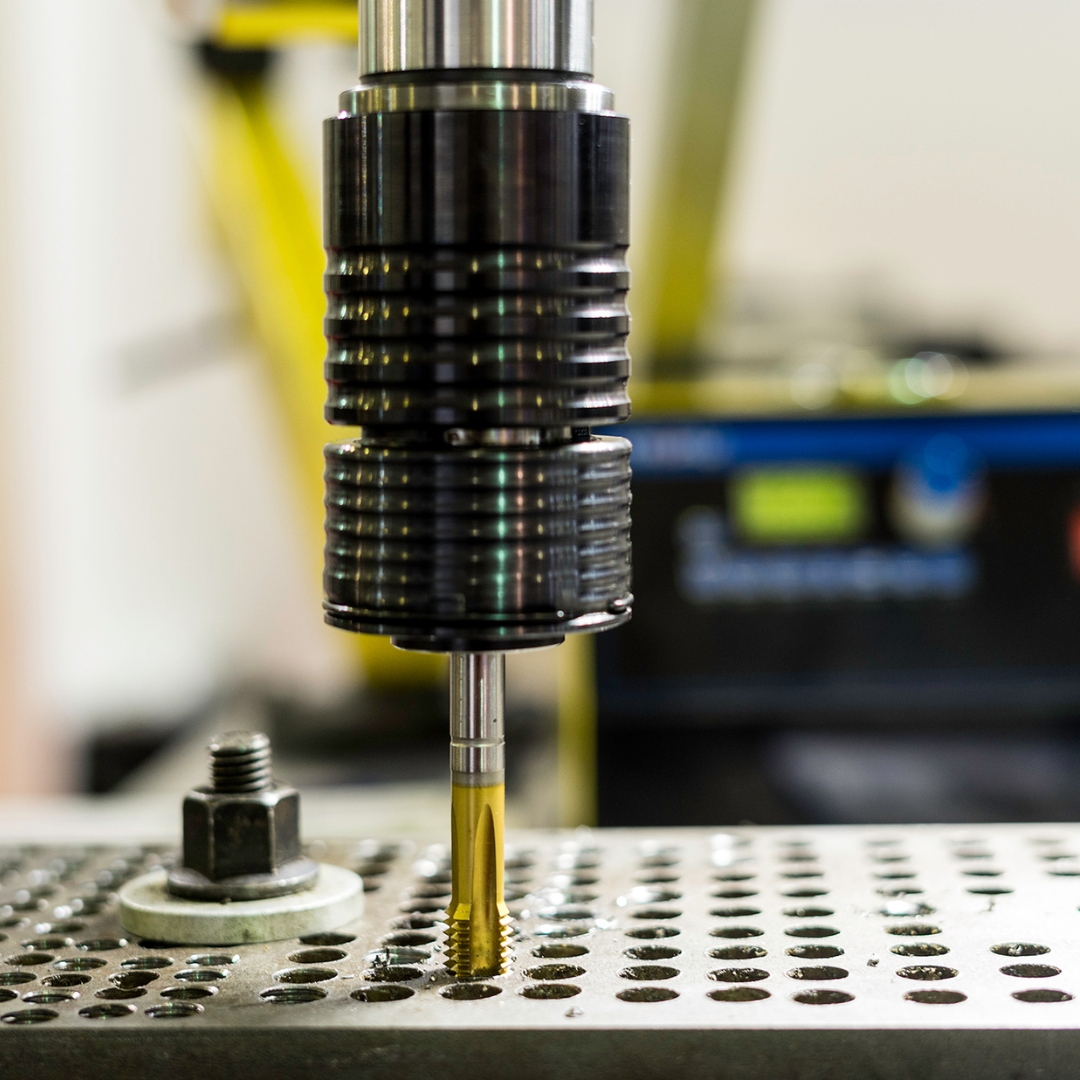

We are equipped with state-of-the-art VMC machines featuring advanced capabilities for milling, drilling, and tapping. These machines guarantee

Precision

Tight tolerances and intricate detail work are achievable due to the advanced technology of our VMCs.

Measuring Equipment

We utilize precision measuring equipment to ensure parts meet exact specifications.

Versatility

Our VMCs can handle a wide range of materials and project requirements.

Skilled Workforce

Our greatest asset is our team of highly skilled and experienced engineers.

Efficiency

Our VMCs can handle a wide range of materials and project requirements.

Advanced Tooling & Software

We invest in high-quality cutting tools and machining software to optimize performance:

Sharp Tools: We utilize premium cutting tools for clean cuts and extended tool life, minimizing downtime and ensuring consistent quality.

CAD/CAM Software: We leverage advanced CAD/CAM software for efficient programming, minimizing errors and optimizing machining processes.

Stringent Quality Control

Maintaining exceptional quality is paramount at TEPL. We have a robust quality control system in place:

Inspections: Thorough inspections are conducted throughout the production process to identify and rectify any potential issues.

Measuring Equipment: We utilize precision measuring equipment to ensure parts meet exact specifications.

Skilled Workforce

Our greatest asset is our team of highly skilled and experienced engineers. Their expertise in:

Safe Work Environment:

We prioritize safety in our workplace. We maintain a clean, organized, and well-maintained workshop environment to ensure the safety of our team and the integrity of your projects.

VMC Operation: Our operators are proficient in running VMC machines, maximizing their capabilities.

Programming & Machining Techniques: The team possesses in-depth knowledge of programming and machining techniques, ensuring optimal results for your projects.

Quality Assurance: Our quality control personnel are vigilant in maintaining the highest quality standards

Continuous Improvement:

We are dedicated to continuous improvement:

Technology Adoption: We actively explore and integrate new advancements in VMC technology to enhance efficiency and capabilities.

Training & Development: We invest in ongoing training for our team to ensure they stay updated with the latest industry trends and best practices.

VL-850-2016

Make-Manford

Bed size-850 x 550 x 550

Vertical Machining Centre

VL-850-2022

Make-Manford

Bed size-850 x 550 x 550

Vertical Machining Centre

VL-1050

Make-Manford

Bed Size 1050 x 650x 650

CNC Turning Center

Make-Manford

DIA 300 x 600

VMC-850

Make-Manford

Bed size-850 x 550 x 550

Vertical Machining Centre

VMC-850

Make-Manford

Bed size-850 x 550 x 550

Vertical Machining Centre

VMC-850

VMC-850

VMC-850

VL-1050

VMC-850

VMC-851

VMC-851

CNC Turning machine

Precision

Tight tolerances and intricate detail work are achievable due to the advanced technology of our VMCs.

Measuring Equipment

We utilize precision measuring equipment to ensure parts meet exact specifications.

Versatility

Our VMCs can handle a wide range of materials and project requirements.

Skilled Workforce

Our greatest asset is our team of highly skilled and experienced engineers.

Efficiency

Our VMCs can handle a wide range of materials and project requirements.

Advanced Tooling & Software

We invest in high-quality cutting tools and machining software to optimize performance:

Sharp Tools: We utilize premium cutting tools for clean cuts and extended tool life, minimizing downtime and ensuring consistent quality.

CAD/CAM Software: We leverage advanced CAD/CAM software for efficient programming, minimizing errors and optimizing machining processes.

Stringent Quality Control

Maintaining exceptional quality is paramount at TEPL. We have a robust quality control system in place:

Inspections: Thorough inspections are conducted throughout the production process to identify and rectify any potential issues.

Measuring Equipment: We utilize precision measuring equipment to ensure parts meet exact specifications.

Skilled Workforce

Our greatest asset is our team of highly skilled and experienced engineers. Their expertise in:

Safe Work Environment:

We prioritize safety in our workplace. We maintain a clean, organized, and well-maintained workshop environment to ensure the safety of our team and the integrity of your projects.

VMC Operation: Our operators are proficient in running VMC machines, maximizing their capabilities.

Programming & Machining Techniques: The team possesses in-depth knowledge of programming and machining techniques, ensuring optimal results for your projects.

Quality Assurance: Our quality control personnel are vigilant in maintaining the highest quality standards

Continuous Improvement:

We are dedicated to continuous improvement:

Technology Adoption: We actively explore and integrate new advancements in VMC technology to enhance efficiency and capabilities.

Training & Development: We invest in ongoing training for our team to ensure they stay updated with the latest industry trends and best practices.

Bandsaw Cutting Machine

Make-Laksman

Model-2016

MI DRO Milling

Make-Laksman

Model-2016

TIG welding Machine

MakeRajkot

Model-Multipurpose

Drilling and Tapping Machine

Make-CKP

Model-M3-M12-2012

Manual Fork lift

Make-Indian

1.5 Tonns